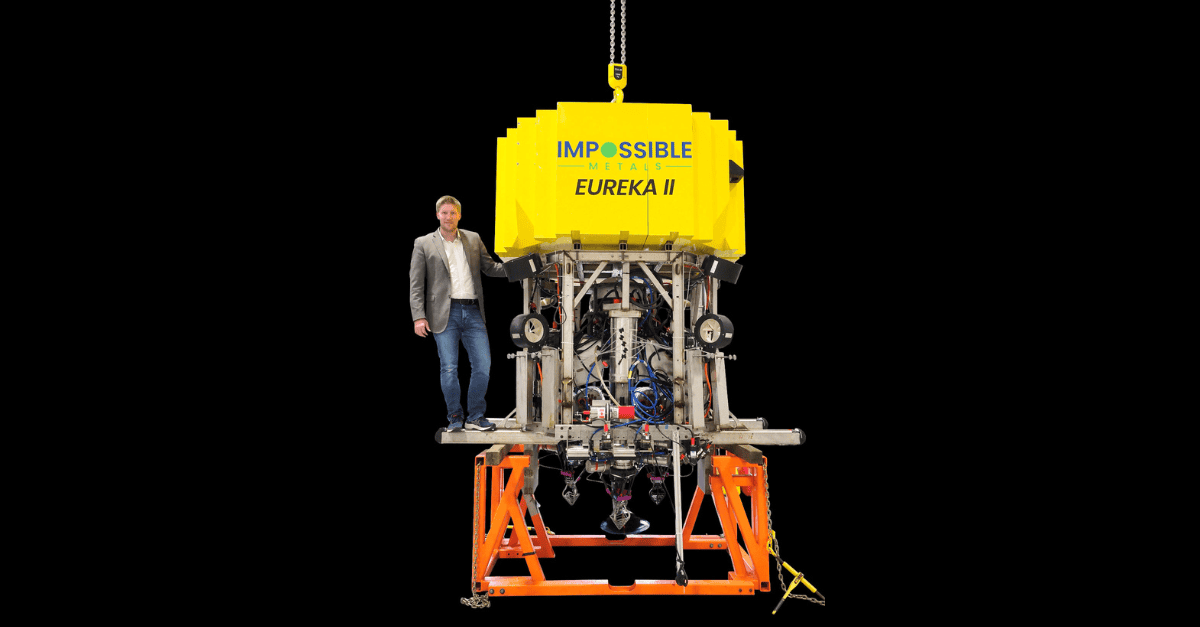

The quest to develop sustainable and efficient technologies for deep-sea mineral collection has led to innovative solutions. Eureka, our advanced autonomous underwater robotics platform, is a prime example of how cutting-edge engineering can address both technical and environmental challenges. At the heart of Eureka are three key enabling technologies that set it apart: advanced image processing, Delta arms for efficient collection, and buoyancy engines designed for dynamic payload management.

Image Processing: Seeing and Protecting the Seafloor

Eureka employs state-of-the-art stereo camera image processing technology to accurately and individually locate valuable nodules while minimizing environmental impact. Using high-resolution cameras and advanced algorithms, the system precisely identifies and maps nodules on the seafloor.

Eureka’s ability to detect signs of life in real time and create exclusion zones around them makes it unique. The exclusion zones ensure that sensitive ecosystems remain undisturbed, reinforcing our commitment to responsible exploration. By integrating machine learning, Eureka continuously improves its ability to distinguish between nodules and biological life, setting a new standard for ethical underwater operations.

Delta Arms: High-Speed Collection with Minimal Disturbance

Traditional methods of collecting seabed resources often significantly disrupt the marine environment. Eureka’s Delta arms, inspired by industrial automation systems, revolutionized this process. These arms are designed for high-speed, precise movements, enabling them to efficiently collect nodules while causing minimal seafloor disturbance.

The Delta arms leverage a lightweight yet robust design, allowing for swift action without compromising on durability. Their modular nature also provides flexibility, enabling Eureka to adapt to various underwater conditions. For example, when nodule sizes vary from location to location, Eureka’s modularity allows for alternate and optimized arms and end effectors to be employed. This approach not only enhances operational efficiency but also minimizes our activities’ environmental footprint.

Buoyancy Engines: Dynamic Payload Management

A core innovation within Eureka is its buoyancy engine system. These engines work by pumping water in and out of a fixed-volume chamber to adjust the overall buoyancy of the system. As nodules are collected, their weight is offset by expelling water from the chambers, maintaining stability and efficiency during operations.

This dynamic approach to buoyancy management ensures that Eureka remains agile and energy-efficient, even as its payload increases in mass. The buoyancy engines contribute to the system’s sustainability and operational endurance by reducing the need for additional power to counteract weight changes.

A Holistic Design for Sustainable Exploration

Integrating these three technologies into Eureka represents a leap forward in underwater robotics. By combining advanced image processing, agile Delta arms, and efficient buoyancy engines, Eureka excels in collecting valuable seabed resources and prioritizes preserving marine ecosystems.

Our commitment to sustainability and technological excellence remains unwavering as we continue to innovate. Eureka is not just a tool for critical mineral collection; it is a testament to what can be achieved when engineering and environmental stewardship go hand in hand.