Buoyancy engines are a component of underwater technology, playing a vital role in enabling the precise movement and stability of submersible systems. From research submarines to deep-sea mining robots, these systems leverage the fundamental principles of buoyancy to achieve controlled operations at incredible depths. At Impossible Metals, our innovative buoyancy engine design takes this concept to a new level, offering a novel approach that addresses the challenges of deep-sea operations. Let’s explore the engineering and physics behind buoyancy engines and why our solution is a game-changer.

Purpose of Buoyancy Engines

Buoyancy engines manage the lift and stability of underwater vehicles, allowing them to ascend, descend, or maintain neutral buoyancy. These systems are critical for applications ranging from scientific exploration to industrial tasks like subsea pipeline inspections and deep-sea mining.

Buoyancy control is achieved through various mechanisms tailored to specific applications. In salvage operations, lift bags and sponsons are commonly used to raise sunken objects. Lift bags are filled with compressed air to displace water and generate upward force, while sponsons provide additional buoyancy and stability. For glider-based robotic submersibles, oil bladder systems are often employed. These systems adjust the vehicle’s buoyancy by moving oil between internal compartments and external bladders, allowing for precise depth control. Submarines, on the other hand, utilize compressed air-based systems within ballast tanks to manage buoyancy. Submarines achieve reliable and controlled vertical movement by filling tanks with water to descend and displacing this water with compressed air to ascend.

Each approach demonstrates the versatility of buoyancy engines in addressing diverse operational needs. However, operating at extreme depths presents unique challenges, necessitating innovative solutions like the one developed by Impossible Metals.

Buoyancy Science

At the heart of buoyancy lies Archimedes’ principle: an object submerged in a fluid experiences an upward force equal to the weight of the fluid it displaces. To achieve neutral buoyancy, the buoyant force must equal the gravitational force acting on the object’s mass. For underwater buoyancy systems, the buoyant force is most commonly increased by increasing the displaced volume. However, increases in buoyancy are also achieved by reducing the mass of the same volume.

Traditional buoyancy systems come in various forms, all of which increase the amount of surrounding water being displaced, including:

- Ballast Tanks: These tanks are used in submarines. They are filled with water to increase mass or air to displace the water and reduce mass, enabling ascent and descent.

- Lift Bags: Common in salvage operations, lift bags use compressed air to provide upward force. However, due to air volume and pressure changes, their performance can be unpredictable at varying depths.

- Sponsons: These are external buoyancy aids that increase stability but lack the fine-tuned control needed for precision operations.

While effective in specific contexts, these traditional methods often face limitations in deep-sea environments, where extreme pressures demand innovative solutions.

Deep Sea Limitations

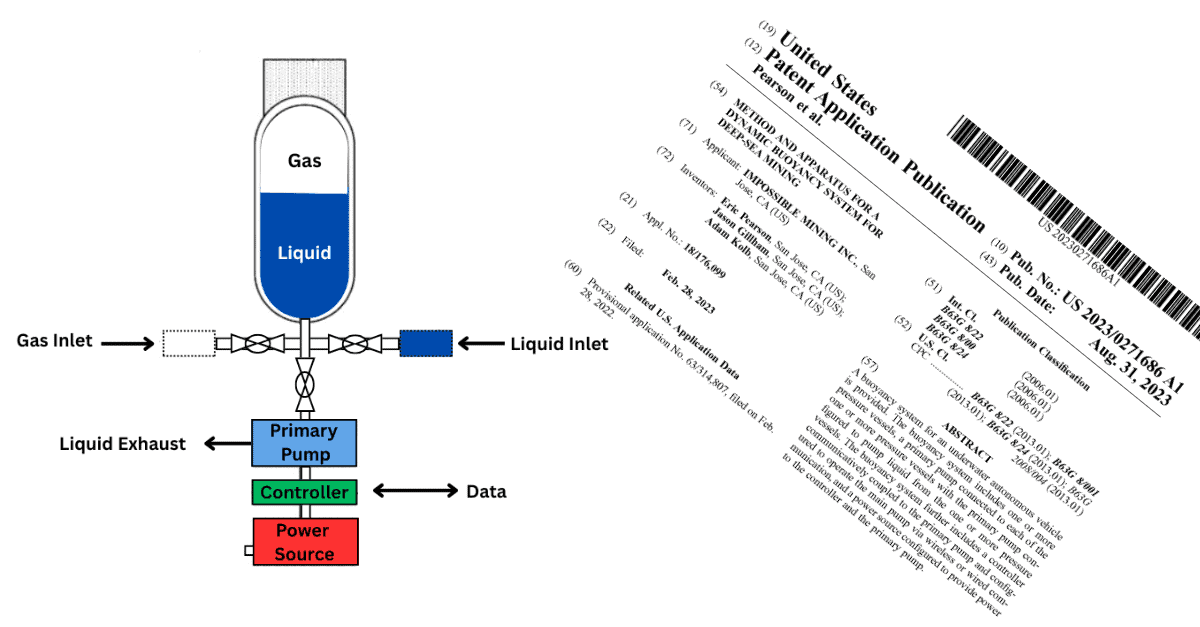

Due to the immense pressures at depth, air density approaches that of water in deep-sea conditions. This makes traditional air-based buoyancy systems less effective, as the buoyant force resulting from the displaced water is nearly completely offset by the mass of the air used to displace the water. Impossible Metals has developed a buoyancy engine with a fixed volume and variable mass to overcome this challenge. Our system pumps water in and out of a sealed chamber, allowing precise control of the overall mass.

This fixed-volume approach offers several advantages:

- Precise Lift Control: By adjusting the mass of water within the chamber, we can fine-tune buoyancy with high accuracy.

- Elimination of Buoyancy Runaway: Unlike lift bags or sponsons, which can experience runaway buoyancy as air expands with decreasing pressure, our system remains stable with a constant force across varying depths.

- Energy Efficiency: The precision control of the system reduces the energy required for buoyancy adjustments, extending the operational endurance of a system using this style of engine.

The innovative design of Impossible Metals’ buoyancy engines is a testament to our commitment to advancing underwater technology. By addressing the challenges of deep-sea buoyancy with a novel approach, we are enabling further exploration of the ocean’s depths. This technology enhances our robotic systems’ performance and sets a new standard for precision lift control in the industry.

As we continue to push the boundaries of what is possible, our buoyancy engines as a component within our overall deep-sea nodule collection vehicles will play a pivotal role in unlocking the deep sea’s potential while preserving its delicate ecosystems.