Frequently Asked Questions (FAQs)

Please contact our team if you have any questions that aren’t covered here or would like to discuss your questions or feedback with Impossible Metals.

Impossible Metals Competitors

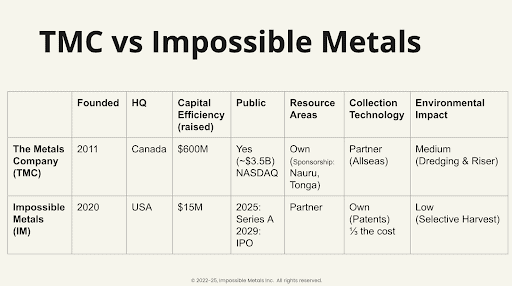

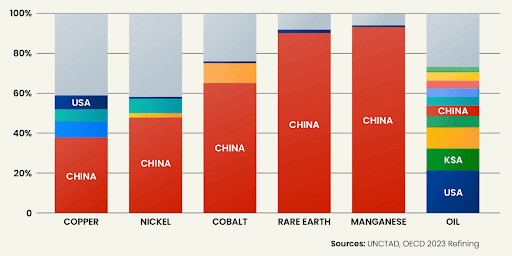

Impossible Metals has competition from land- and ocean-based mining companies for nickel, cobalt, copper, and manganese.

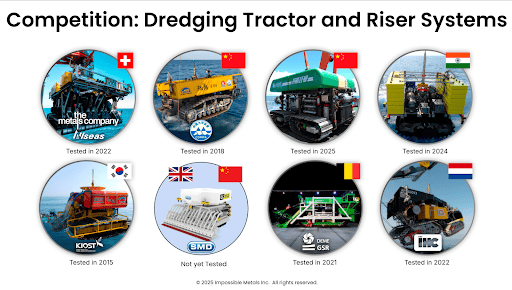

A number of companies have conducted dredging tractor and riser system deep sea trials; however, the ship-to-ship transfer of the nodules has not been tested. The ship-to-ship transfer of the nodules in the ocean is complex and will likely require very specialized transport ships, including dynamic positioning (DP) and dewatering technology. This article includes more details on this topic.

G.5 has moved to Section I.

The U.S. Army Corps of Engineers defines dredging as “A dredge is a machine that scoops or suctions sediment from the bottom of waterways…”

Although companies are using the ‘Coanda effect,’ it is still dredging. The leading dredging companies have built polymetallic nodule collection systems, e.g., All Seas, DEME/GSR, Royal IHC, etc. Dredging tractors for deep sea mining were first described in a 1965 patent, 3,456,371.

G.7 has moved to Section I.