Frequently Asked Questions (FAQs)

Please contact our team if you have any questions that aren’t covered here or would like to discuss your questions or feedback with Impossible Metals.

Market for Deep Sea Critical Minerals

The demand for nickel, cobalt, copper, and manganese, materials crucial for producing advanced technologies in defense, energy, and infrastructure, has skyrocketed. Projections from the World Bank indicate that demand for these metals will increase by 500% by 2050, raising concerns about their availability and sustainability on a global scale. Without deep-sea minerals, 388 new mines must be built by 2030 to provide the necessary minerals to meet this demand.

Recycling can be a part of the solution, as metals are highly reusable, but it is insufficient. A new electric vehicle (EV) won’t be scrapped for 10 to 15 years. Its battery pack, while no longer able to power a vehicle, can last 15 to 20 years and may find a second life by storing wind or solar energy before being recycled. The International Energy Agency forecasts that the secondary supply of batteries and the reuse of nickel will represent just 3% of total demand in 2030 and 10% in 2040. To help close the demand gap, mining for new metals will still be essential.

Proposals to reduce demand fall into two categories:

The first category is to reduce demand by reducing car dependence in wealthy nations, which sounds doable in theory but can have significant implications for GDP and the economy. For example, in the U.S., that could require the migration of 50% to 75% of the population from rural and low-density communities to medium-density communities to take advantage of cycling, biking, walking, and mass transit. This migration would impact hundreds of millions of Americans and require significant policy, urban, infrastructure, and transportation changes that could take decades to implement and bring their own challenges.

The second proposed solution would limit access to modern technology like air conditioning (AC) and electric vehicles (EVs) in developing countries like India and in Africa. While climate change affects the entire planet, poorer countries are more severely affected, and their need for AC to reduce heat stroke and improve daily life is already significant. When Harvard China Project researchers modeled future air conditioning demand, they found an enormous gap between current AC capacity (2.8 billion people live in the hottest parts of the world, but only 8% of them have home AC) and the AC capacity needed by 2050 to save lives. In addition, a World Bank study of 20 developing countries found that EVs would be an economic and environmental win for more than half of those countries. While it is essential to dig into how to reduce the overall demand for critical metals to attain net-zero goals, it’s clear that the solution needs to be more practical and humane.

While new battery chemistries are emerging, nickel and cobalt are likely to remain important for longer-range EVs and many non-battery uses.

Nickel and cobalt are used in many but not all battery chemistries. Today, they are mainly used in lithium, nickel, manganese, cobalt oxides (NMC), and lithium nickel, cobalt, aluminum, and oxides (NCA). Lithium iron phosphate batteries (LFP) are popular in China and do not use nickel or cobalt. However, LFP batteries are also significantly heavier, resulting in less range in an EV. Manganese-rich NMC could be a cheap alternative to LFP/LMFP, avoiding dependency on Chinese supply chains without sacrificing range. Cheaper, sustainably mined Cobalt from deep sea minerals would make high-voltage mid-nickel NMC an additional alternative. Nickel and cobalt are also used in many non-battery energy transition applications, including solar, wind, and nuclear power.

External industry analysts, such as Roland Berger, Benchmark Mineral Intelligence, etc., forecast that L(M)FP will account for around 35% of North American EV batteries in 2030. North American EVs will also use nickel-based (NMC) and iron-based (LFP) batteries. LFP is better for small pack sizes and cheaper vehicles, which are very popular in China. NMC has higher energy density and is best for long-range vehicles with bigger pack sizes.

LFP is primarily a Chinese technology today, so North America has no volume manufacturing. If you buy a car with Chinese batteries, you do not qualify for the Inflation Reduction Act (IRA)’s $7,500 tax rebate because they contain materials from a “foreign entity of concern.” For example, the lowest-cost Model 3 Teslas, which use LFP batteries currently do not qualify for the credit,but the long-range vehicles do qualify, making them cheaper on an after-tax basis than the LFP-based vehicles and offering almost 100 more miles of range. LFP also has a very low recycling value. NMC has large recycling values; if you factor in the end-of-life recycling value, NMC is cost-competitive.

Finally, while additional battery chemistries are being developed today, some of which will not require nickel and cobalt, they are unlikely to make a significant impact on climate goals in the next one to two decades. It typically takes 20 years after a new battery chemistry is invented before a Western automotive manufacturer deploys it at scale. Western automotive manufacturers need many years of samples from the volume production factory before the battery cells will be qualified.

For more details, see our blog post, “Inconvenient Facts About LFP Batteries”.

According to S&P Global, mining companies take an average of 23 years from discovery to production; in the US, it’s 29 years.

Deep sea minerals will significantly lower recovery costs compared to new land-based mines. Given the high ore grade, four metals in one ore, and low infrastructure costs, deep sea minerals extracted from polymetallic nodules will be the lowest cost of all forms of mining. In addition, the ocean seabed is the world’s largest source of nickel, cobalt, and manganese, and selective harvesting will have the lowest environmental impact. For more details, see this blog post, “Why Will Deep Sea Mining Be Less Expensive Than Traditional Land-Based Mining?”

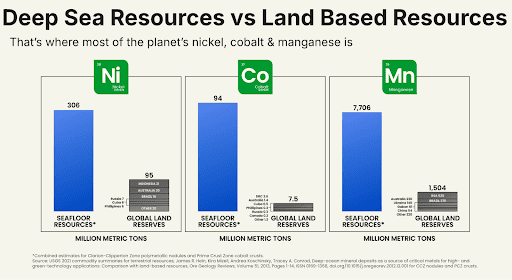

Yes. The known reserves of Ni, Co, and Mn in the ocean are between 3x and 10x the known reserves on land. Our parallel fleet of underwater robots can collect substantial amounts of critical materials, and replication of a single project can increase productivity.

Yes, we estimate that our system will be 15x lower cost than the average nickel mine in 2024. See this blog post to learn more.

Yes. Existing land-based mines will continue to operate, but new land-based mines will not open after deep sea minerals ramp into production. This is because of the cost advantages of extracting deep sea minerals, the size of the resource, and the lower Environmental, Social, and Governance (ESG) impacts.

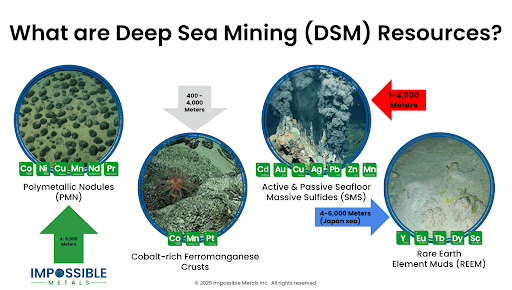

There are four potential sources of deep sea minerals: polymetallic nodules, cobalt-rich ferromanganese crusts, seafloor massive sulfides, and rare earth element muds.

Polymetallic Nodules (PMN) contain nickel, cobalt, copper, and manganese. These potato-sized rocks are found on the abyssal plains lying on the seabed sediment. They do not require cutting, blasting, or tunneling. This is the exclusive focus of Impossible Metals. Cobalt-rich Ferromanganese Crusts (CFC) mainly contain cobalt. They form on sediment-free rock surfaces around oceanic seamounts, ocean plateaus, and other elevated features. Seafloor Massive Sulfides (SMS) mainly contain copper, lead, zinc, and some gold and silver. They appear on and within the seafloor when mineralized water discharges from a hydrothermal vent. The hot, mineral-rich water precipitates and condenses when it meets cold seawater. Most proposed mining is focused on extinct hydrothermal vents. Rare Earth Element Muds (REEM) mainly contain rare earth elements in the seabed sediment.

71% of our planet’s surface area is oceans, and only 29% is land. We have mined on land since the Bronze Age, so the world’s oceans contain significantly more nickel, cobalt, and manganese reserves.

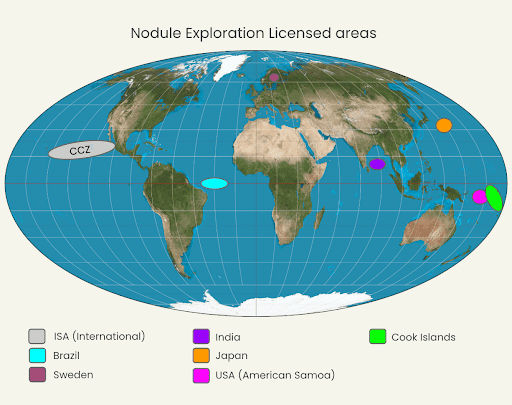

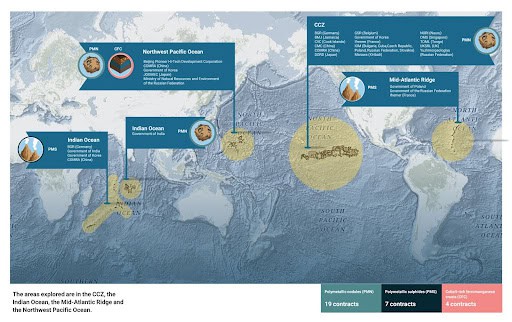

All of the world’s oceans contain deep sea minerals. The international seabed area, under ISA jurisdiction, has issued exploration licenses in the Clarion-Clipperton Zone (CCZ), the Indian Ocean, the Mid-Atlantic Ridge, and the Pacific Ocean.

Many countries contain deep sea minerals within their EEZs, such as the Cook Islands, Norway, Japan, Sweden, India, the Kingdom of Saudi Arabia, American Samoa, Papua New Guinea, Chile, the United States, Brazil, and China. See countries developing subsea minerals in their EEZs.